Leather engraving isn't just an art—it's a craft that laser enthusiasts and DIY creators have elevated to new levels. If you're someone who's into laser engraving, you're probably familiar with how crucial it is to have the right settings, the right designs, and, most importantly, the right materials. Whether you're engraving leather for custom wallets, belts, or even experimental pieces of art, premium leather consumables can make or break your final product. This blog is here to guide you through choosing the best leather and settings to achieve that perfect, detailed finish on every project.

Why Your Material Choice Matters

When it comes to leather engraving, not all leather is created equal. As someone who's likely familiar with the intricacies of laser engraving, you know how even the smallest variables—like leather quality—can influence the final output. A cheap, low-quality piece of leather can result in uneven engraving, burnt edges, and a finished product that looks unprofessional.

That’s where premium materials come into play. Using high-quality leather, like those found in Great Carve's collection, ensures you get cleaner cuts, sharper details, and a better overall finish. Whether you're customizing personal items or creating products for sale, your material choice will directly impact the outcome.

Different Types of Leather

-

Full-Grain Leather: The best option for laser engraving, providing a durable and high-quality surface for intricate designs. The natural grain allows for a textured, detailed engraving that looks professional.

-

Top-Grain Leather: Slightly cheaper but still a great option. It provides a smoother surface that works well for more minimalist designs or patterns that don’t require a ton of detail.

-

Bonded Leather: This is a lower-quality leather that's often made from leftover scraps. While it's cheaper, it’s not the best choice for laser engraving because the inconsistent material may lead to irregular cuts.

Each leather type offers different properties, and as you might already know, dialing in the right machine settings for each is crucial. However, by starting with premium materials, you're already ensuring a smoother process.

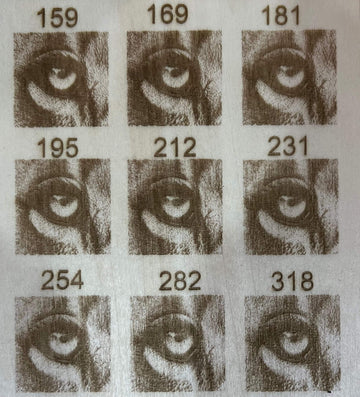

Dialing in Your Machine Settings for Leather Engraving

Now that you’ve selected the perfect leather for your project, it’s time to focus on the technical aspect of leather engraving: machine settings. This is where things can get tricky, especially if you’re switching between different materials frequently. But fear not—here are some tips to keep your engravings crisp and clean, every time.

Power and Speed Settings

The key to achieving detailed and clean engravings on leather is finding the right balance between power and speed. If you’re working with thicker, more durable leather like full-grain, you’ll need higher power settings to cut through the material, but be careful—too much power can burn the edges. On the flip side, thinner leather types like top-grain may require lower power but faster speeds to avoid any scorching.

For most DIY engravers, a good starting point is:

-

Full-Grain Leather: 30-40% power, 300-400mm/s speed.

-

Top-Grain Leather: 20-30% power, 500-600mm/s speed.

Every laser engraving machine is different, so be sure to test these settings on a scrap piece of leather before starting on your final project. It’s worth spending a little extra time fine-tuning these settings so you don’t end up wasting materials.

Overcoming Common Leather Engraving Challenges

As any DIY enthusiast knows, no project goes 100% according to plan, especially when working with complex machines like laser engravers. Here are some common issues you may face and how to overcome them.

Burnt Edges

This is one of the most frequent issues DIY laser engravers face when working with leather. The cause? Too much power or not enough airflow. To avoid burnt edges, try lowering your power settings and increasing your speed. If that doesn’t work, consider adding an air assist to blow away any excess heat and smoke.

Inconsistent Depth

If your engravings aren’t consistent in depth, it’s likely due to the quality of your leather or uneven surface areas. Using premium leather, such as Great Carve’s premium leather, ensures that the material is uniform and reliable, reducing inconsistencies in your final product.

Uneven Cuts

This is usually a sign that your machine settings aren’t dialed in properly. If your cuts are uneven, try increasing the power slightly or adjusting the focal length of your laser. A few simple tweaks can make a world of difference.

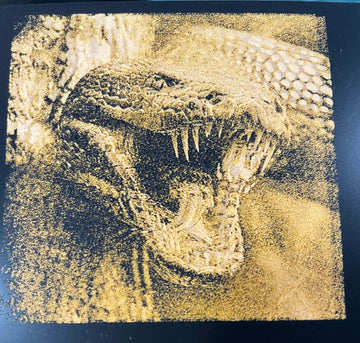

Creative Applications of Leather Engraving

One of the best things about working with leather is its versatility. The possibilities are endless, from custom belts and wallets to larger-scale projects like bags or even home décor. Here are a few popular applications that DIY makers and tech enthusiasts love to work on:

-

Custom Wallets: Personalize with names, initials, or logos.

-

Leather Belts: Great for gifts or even small-scale retail businesses.

-

Home Décor: Leather wall art, custom coasters, and more.

And this is where your consumables come in! Your premium leather products, like those sold in your store, are ideal for creating high-quality, professional-looking engravings for any of these projects. For makers selling on Etsy or at local craft fairs, investing in high-quality leather can help them stand out from the competition.

Why Premium Materials Matter

If you’re passionate about laser engraving, you already understand the importance of using quality materials. Using cheap leather can compromise your designs, leaving you with burnt edges, inconsistent cuts, or even wasted projects. That’s why premium consumables are crucial for anyone serious about their craft.

At Great Carve, we understand the needs of laser engraving enthusiasts, which is why we offer only the best leather options. Our leather is tested and proven to work seamlessly with laser engraving machines, providing you with clean, consistent, and professional results every time.

Elevate Your DIY Projects with the Right Consumables

When it comes to laser engraving, the materials you use can make all the difference. Whether you’re a hobbyist or a professional, using high-quality leather ensures that your designs come out looking sharp, detailed, and professional.

So next time you’re planning your next big engraving project, don’t settle for anything less than the best. Check out our collection of premium leather materials and elevate your creations to the next level!

Final Thoughts

Leather engraving is a deeply satisfying craft, especially when you get those perfect, crisp results that leave a lasting impression. With the right combination of materials, settings, and techniques, you can create stunning pieces that last a lifetime. And remember, as any serious maker knows, the quality of your consumables is just as important as the quality of your tools.

Happy engraving, and may your projects be as sharp as your lasers!